The Role of Gearbox Manufacturers in the Food Industry

When you consider the food industry, you might not immediately think about the crucial role of gearbox manufacturers. Yet, these specialized companies are essential in ensuring machinery runs smoothly and safely. From enhancing efficiency to minimizing contamination risks, their innovations directly impact food quality and safety standards. As you explore how these manufacturers contribute to the overall reliability of food processing operations, you might find some surprising trends and technologies that are shaping the future of the industry. What trends are emerging that could redefine this vital sector?

Importance of Gearbox Efficiency

When it comes to the food industry, gearbox efficiency plays a critical role in ensuring smooth operations. You rely on efficient gearboxes to maintain production levels, reduce downtime, and manage costs effectively. An efficient gearbox minimizes energy loss, which translates to lower electricity bills and a reduced carbon footprint. This efficiency is vital in a sector where margins can be razor-thin.

You’ll also find that efficient gearboxes help prolong the lifespan of equipment. By reducing wear and tear, they decrease the frequency of maintenance and replacement, allowing you to allocate resources more effectively. Furthermore, when gearboxes operate smoothly, they enhance the overall performance of machinery, which is crucial in food processing where timing and precision are key.

Additionally, having efficient gearboxes can improve safety in your operations. When machines run smoothly, the risk of malfunctions decreases, ensuring a safer work environment for your employees.

In a fast-paced industry like food production, you can’t afford to overlook the importance of gearbox efficiency. Investing in high-quality gearboxes isn’t just a choice; it’s a necessity for maintaining productivity and quality while meeting stringent industry standards.

Types of Gearboxes Used

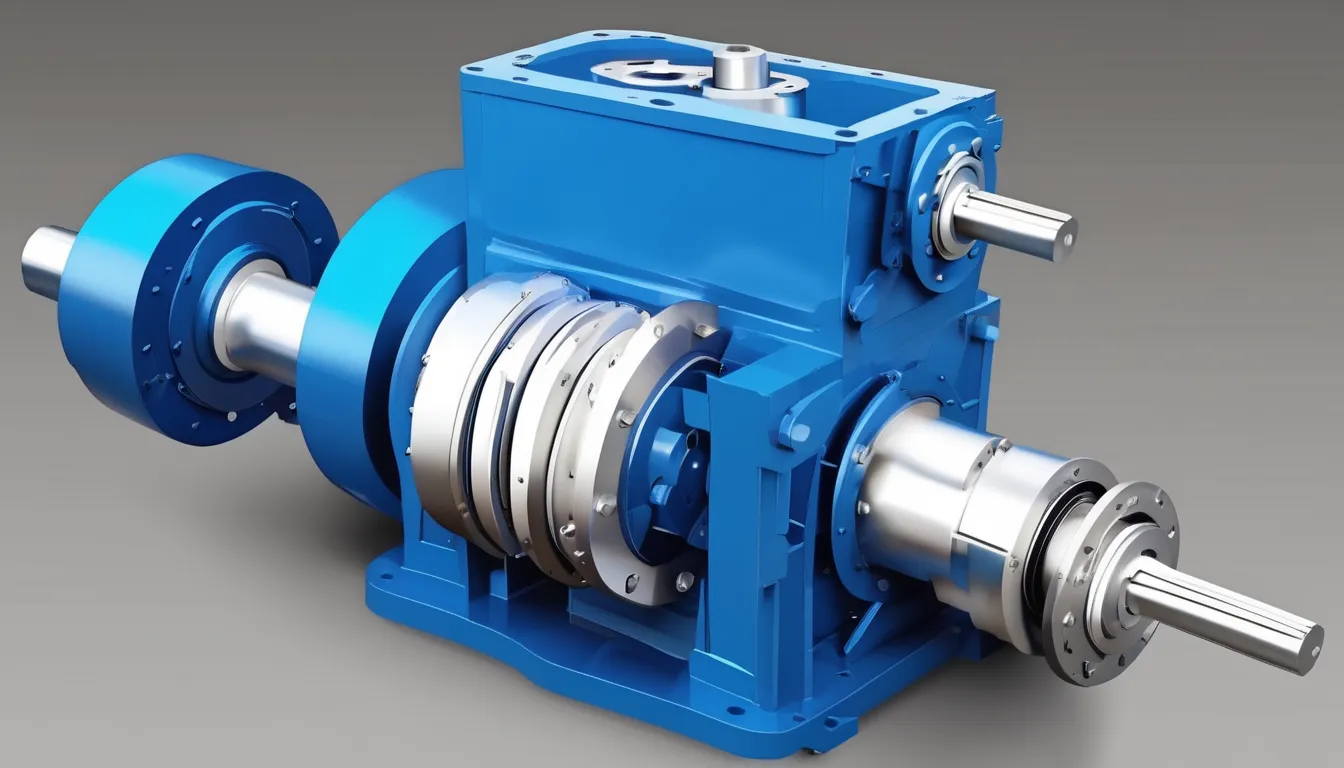

Understanding the types of gearboxes used in the food industry is vital for maximizing efficiency and performance. Different applications require specific gearbox types to ensure optimal functionality.

One common type is the helical gearbox, known for its smooth operation and high efficiency. You’ll find these in conveyor systems where noise reduction and durability are key.

Then there are worm gearboxes, which excel in providing high torque at low speeds. They’re ideal for applications requiring significant reduction ratios.

Bevel gearboxes are also popular; they can change the direction of the drive shaft, making them useful in space-restricted installations.

If you’re focusing on heavy-duty applications, planetary gearboxes might be your best bet due to their compact design and ability to handle large loads.

Lastly, consider the need for sanitary gearboxes, specifically designed to meet hygiene standards in food processing. These often feature smooth surfaces and easy disassembly for cleaning.

Impact on Food Safety

In the food industry, china Custom gear solutions es play a crucial role in ensuring food safety. They’re responsible for driving various equipment, from mixers to conveyor belts, which directly affect food processing. If a gearbox fails, it can lead to contamination, spoilage, or a complete halt in production. That’s why choosing the right gearbox manufacturer is vital for maintaining compliance with safety regulations.

To illustrate the impact of gearboxes on food safety, consider the following aspects:

| Aspect | Importance | Consequences of Failure |

|---|---|---|

| Material Quality | Non-corrosive materials prevent rust | Contamination of food products |

| Sealing Systems | Prevents ingress of contaminants | Increased risk of spoilage |

| Maintenance Protocols | Regular checks ensure proper function | Unexpected downtime |

| Temperature Control | Essential for perishable goods | Food safety violations |

| Compliance Certifications | Ensures adherence to food safety laws | Legal repercussions |

Innovations in Gearbox Design

Innovative gearbox designs are transforming the food industry, enhancing both efficiency and safety. As you explore these advancements, you’ll find that manufacturers are focusing on materials that resist corrosion and contamination, ensuring that your equipment remains compliant with stringent hygiene standards.

You might also notice the shift towards compact and lightweight designs. These innovations make installation and maintenance easier, saving you both time and resources. Moreover, improved gear ratios and configurations can lead to better energy efficiency, resulting in reduced operational costs.

Another key development is the integration of smart technology. With IoT-enabled gearboxes, you can monitor performance in real-time, allowing you to predict failures before they occur. This proactive approach helps you maintain production schedules and avoid costly downtime.

Noise reduction is yet another focus area. Modern gearboxes are designed to operate quietly, which contributes to a more pleasant working environment and aligns with regulatory requirements regarding noise pollution.

Future Trends in Gear Technology

The future of gear technology in the food industry is set to be shaped by advancements that prioritize sustainability and customization. As you navigate this evolving landscape, you’ll notice a growing emphasis on eco-friendly materials and energy-efficient designs. Manufacturers are increasingly focusing on reducing their carbon footprint while maintaining performance and reliability.

Customization will also play a key role. As you work with suppliers, you’ll find that tailored solutions are becoming more common. This trend allows you to meet specific operational needs, enhancing efficiency and productivity.

Moreover, digitalization and smart technology are transforming gear systems. You’ll see a rise in predictive maintenance, where sensors monitor gear performance in real time, preventing costly downtime. This proactive approach not only saves money but also extends the lifespan of your equipment.

Lastly, modular design is gaining traction, allowing for easier upgrades and replacements. You’ll appreciate how this flexibility can adapt to changing market demands and technological advancements.

Conclusion

In conclusion, gearbox manufacturers are essential to the food industry, ensuring machinery operates efficiently and safely. Their specialized gear solutions not only enhance performance but also play a crucial role in maintaining food safety standards. With ongoing innovations and a focus on sustainability, these manufacturers are shaping the future of food processing. By investing in high-quality gearboxes, you’re not just improving your operations—you’re also contributing to a safer and more efficient food supply chain.