Sympathy The Functionality, Applications, And Grandness Of Hydraulic Gear Pumps In Bodoni Font Machinery And Heavy-duty Systems

پمپ دنده ای gear pumps are essential components in the operation of hydraulic systems, playing an necessity role in converting mechanical vitality into mechanics vitality. These pumps are premeditated to give a homogenous flow of pressurised hydraulic fluid, which powers various machinery and . Their functionality relies on the rotation of gears, which create a vacuum-clean to draw fluid into the pump and then force the changeful out under pressure. The simple mindedness, lastingness, and efficiency of mechanics gear pumps have made them a desirable choice in many industrial applications, especially where high power density and dependability are material.

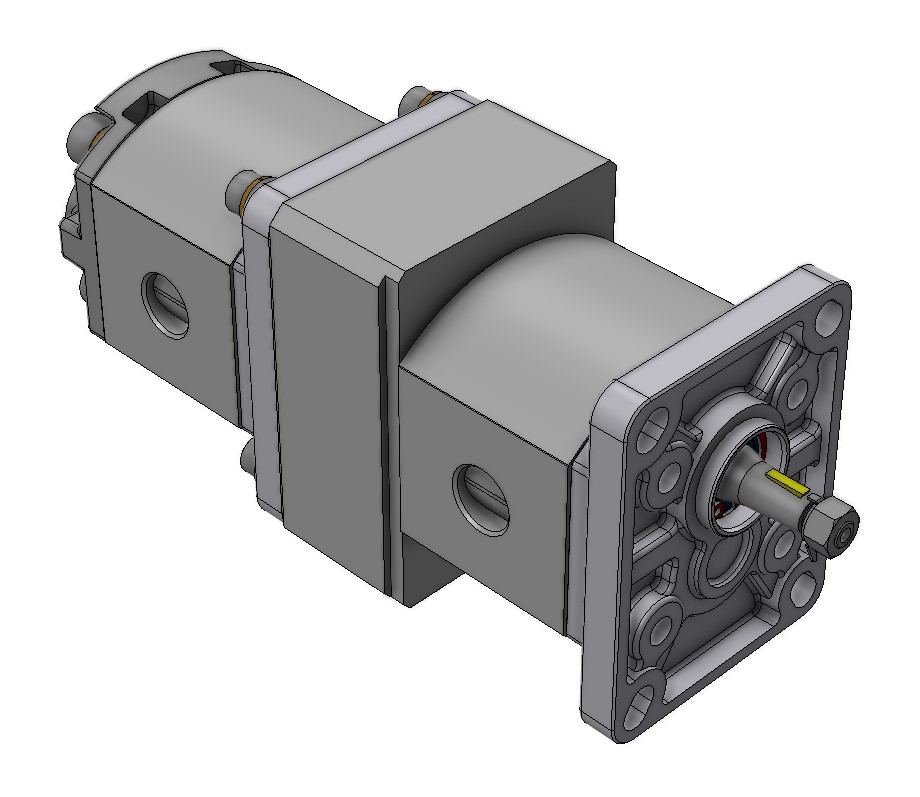

The construction of a hydraulic gear pump involves two interlock gears housed in a case. These gears typically of one drive gear, which is battery-powered by an motor or , and one driven gear. The teeth of the gears mesh together tightly, ensuring the smooth over social movement of changeable from the inlet to the wall socket port. As the gears splay, they trap fluid between the teeth and the casing, creating suction to draw in the hydraulic changeful from the reservoir. Once trapped, the changeful is carried around the gears and is then unscheduled through the port under squeeze as the gears bear on to splay. This process results in the perpetual flow of unstable necessary for the operation of various hydraulic systems.

Hydraulic gear pumps are typically classified into two types: external and intramural gear pumps. External gear pumps are the most common type, where the gears are set outside each other and rotate in contrary directions. The intragroup gear pump, on the other hand, uses a set of gears within each other, with the inner gear being motivated and the outward gear performing as a casing. Each type has its unique advantages, such as the gear pump’s higher volumetric and the internal gear pump’s quieter operation and better performance in handling thick fluids.

One of the key reasons for the general use of mechanics gear pumps is their power to high pressures and flow rates. This makes them indispensable in industries like construction, mining, farming, and manufacturing, where right mechanics systems are necessary to operate such as cranes, excavators, tractors, and forklifts. In these industries, hydraulic gear pumps are causative for generating the forc that powers the machinery’s front and surgical operation, thus ensuring smooth and competent public presentation.

Another significant vantage of mechanics gear pumps is their cost-effectiveness and simpleton plan. These pumps are relatively easy to maintain, which contributes to rock-bottom downtime and operative in industries that rely on ceaseless surgical operation. Their design allows them to work in effect with a wide straddle of fluids, including oil, water, and other mechanics fluids, qualification them highly versatile in various applications. Moreover, because of their compact design, they can be installed in systems with limited quad, further enhancing their adaptability.

However, despite their many advantages, mechanics gear pumps do have limitations. For instance, they are typically less efficient than other types of mechanics pumps, such as piston or vane pumps, especially at high pressures and flow rates. They also produce more noise and vibe compared to other pumps, which can be a touch on in environments where quiesce surgical operation is a priority. Additionally, the use of mechanics gear pumps in applications with extremely polluted or abrasive material fluids can lead to inflated wear and tear, shortening the pump’s life-time.

In conclusion, mechanics gear pumps are an necessity element of many heavy-duty systems due to their efficiency, simpleness, and dependability. They play a polar role in ensuring the smooth over surgery of machinery that relies on hydraulic superpowe for its functions. While they do have some limitations, their advantages in cost-effectiveness and versatility make them an obligatory part of Bodoni font industrial trading operations. Their ability to provide a becalm flow of pressurised unstable ensures that industries across the globe can maintain their machinery, reduce downtime, and step-up productivity.