Key Features of High Performance Turbo Expanders

When you consider high-performance turbo expanders, several key features stand out that contribute to their efficiency and reliability. You’ll notice the importance of aerodynamic rotor blades designed for optimal gas flow, along with advanced sealing technologies that significantly reduce leakage. Moreover, the use of innovative materials like titanium alloys can’t be overlooked, as they play a crucial role in enhancing durability. However, there’s much more to these systems, especially when it comes to their design and control features that adapt to varying operational demands. What could these additional elements be?

Efficiency Enhancements

When it comes to high-performance turbo expanders, efficiency enhancements can significantly boost overall system performance. You’ll want to focus on optimizing several key areas to achieve this.

First, consider the aerodynamic design of the expander. By fine-tuning the blade shapes and angles, you can minimize drag and maximize energy extraction, leading to improved efficiency.

Next, pay attention to the operating conditions. Maintaining optimal inlet temperature and pressure can enhance performance. You might also explore advanced control strategies that adapt in real-time to changing conditions, ensuring the expander operates at its peak efficiency.

Another essential aspect is regular maintenance. Keeping the expander free from fouling and wear can prevent efficiency losses over time.

Additionally, you should evaluate the entire system layout. Reducing pressure drops in piping and ensuring proper insulation can make a noticeable difference in overall efficiency.

Lastly, implementing precise measurement and monitoring tools will help you identify areas for improvement. By focusing on these efficiency enhancements, you’ll not only boost the performance of your turbo expander but also contribute to a more sustainable, cost-effective operation in the long run.

Advanced Materials

High-performance turbo expanders rely heavily on advanced materials to enhance their durability and efficiency. You’ll notice that these materials are specifically chosen for their ability to withstand extreme temperatures and pressures, which are common in turbo expander applications.

For instance, titanium alloys and nickel-based superalloys are often used due to their excellent strength-to-weight ratios and resistance to corrosion.

When you’re evaluating turbo expanders, focus on components like the rotor and casing. Manufacturers often utilize composite materials that combine lightweight properties with high tensile strength. This not only reduces the overall weight but also improves the expander’s performance.

Additionally, advanced coatings can be applied to various parts of the turbo expander. These coatings help minimize wear and tear while enhancing thermal resistance, making the system more efficient over time.

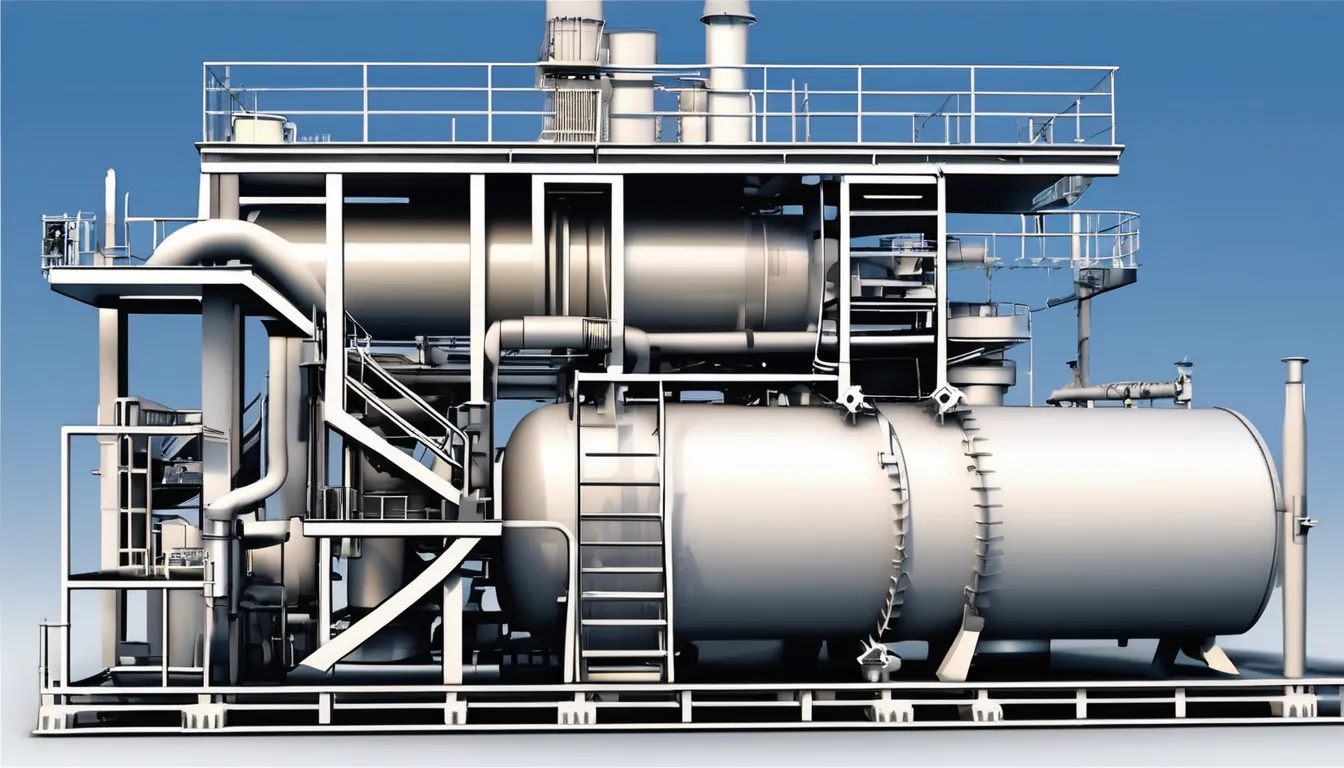

Innovative Design Features

Turbo expanders often incorporate innovative design features that significantly boost their operational efficiency and performance. One key aspect is the aerodynamic design of the rotor blades. By optimizing blade shapes and angles, manufacturers enhance the flow of gas, reducing losses and maximizing energy extraction. This attention to detail means you’ll benefit from improved performance in your applications.

Another notable feature is the integration of advanced sealing technologies. These seals minimize leakage, ensuring that the system maintains optimal pressure and flow rates. With reduced leakage, you can expect higher efficiency and lower operational costs over time.

Moreover, many turbo expanders now utilize modular designs. This allows for easier maintenance and upgrades, meaning you can adapt your system to meet changing demands without a complete overhaul. You’ll also find that some models feature variable geometry, which enables adjustments based on operating conditions. This adaptability means your expander will always perform at its best.

Lastly, innovative cooling techniques are employed to manage temperature effectively. Keeping the components within optimal thermal limits not only extends their lifespan but also enhances overall reliability. With these design features, you’re ensuring that your turbo expander operates efficiently and effectively.

Control Systems

Utilizing advanced control systems, modern Turbo Expander s achieve precise management of operational parameters, ensuring optimal performance. These systems enable real-time monitoring and adjustments, allowing you to respond promptly to changing conditions. By integrating sophisticated algorithms, you can enhance efficiency and reliability, maximizing energy recovery.

A key aspect of these control systems is their ability to adapt to varying loads and environmental conditions. This adaptability ensures that the turbo expander operates within its optimal range, minimizing wear and maximizing output.

Here’s a quick comparison of different control strategies:

| Control Strategy | Advantages | Disadvantages |

|---|---|---|

| PID Control | Simple, well-understood | Limited adaptability |

| Fuzzy Logic | Handles uncertainty | More complex to implement |

| Model Predictive | Anticipates future states | High computational demand |

Maintenance and Reliability

Maintenance is crucial for ensuring the reliability and longevity of turbo expanders. Regular inspections and servicing help you identify potential issues before they escalate, allowing you to keep your system running smoothly.

It’s essential to establish a routine maintenance schedule that includes checks on critical components like bearings, seals, and the rotor assembly. You should also pay attention to lubrication systems, as proper lubrication minimizes wear and tear.

Monitoring vibration levels can provide insights into the operational health of the expander, enabling you to catch imbalances early. Additionally, keeping the air intake and exhaust clean prevents contaminants from affecting performance.

When it comes to reliability, always use genuine replacement parts. They’re specifically designed to meet your turbo expander’s specifications, ensuring optimal performance.

Don’t forget to document all maintenance activities—this record can be invaluable for troubleshooting and future planning.

Conclusion

In conclusion, high-performance turbo expanders stand out due to their efficiency enhancements, advanced materials, and innovative design features. You’ll appreciate how real-time monitoring and sophisticated control systems boost their adaptability, ensuring they meet varying operational needs. Plus, the modular designs make maintenance a breeze, enhancing reliability over time. By investing in these cutting-edge technologies, you’ll not only optimize performance but also ensure durability, making high-performance turbo expanders a smart choice for any application.